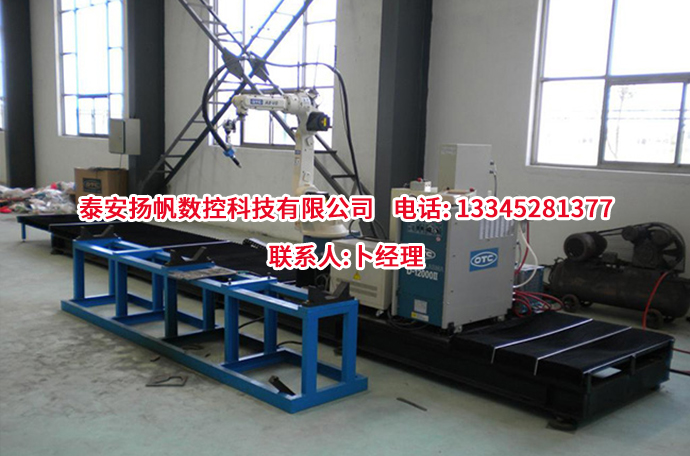

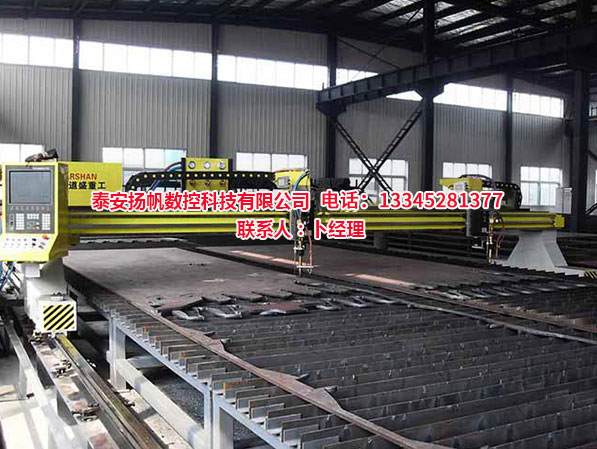

焊機機器人應用的實際意義

來源:http://niuniury.com/ 發(fā)布時間:2021-11-06 瀏覽次數(shù):0

焊接機器人應用的重要意義

Significance of welding robot application

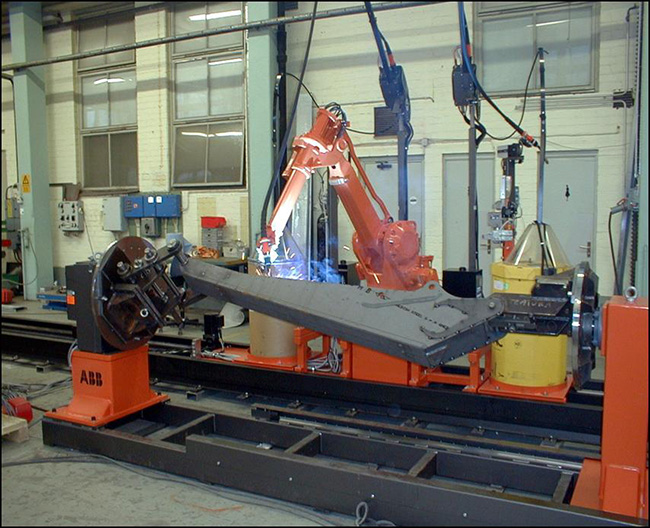

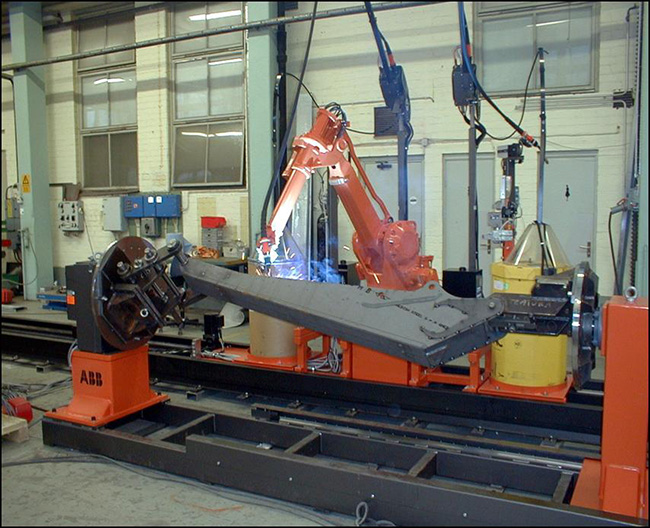

1.焊縫質量穩(wěn)定,保證其均一性。焊接參數(shù)如焊接電流、電壓、焊接速度和干伸長量等對焊接結果有著決定作用。采用機器人焊接時,每條焊縫的焊接參數(shù)都是恒定的,焊縫質量受人為因素影響較小,降低了對工人操作技術的要求,因此焊接質量穩(wěn)定。而人工焊接時,焊接速度、干伸長量等都是變化的,很難做到質量的均一性。

1. The weld quality is stable to ensure its uniformity. Welding parameters such as welding current, voltage, welding speed and dry elongation play a decisive role in the welding results. When robot welding is adopted, the welding parameters of each weld are constant, and the weld quality is less affected by human factors, which reduces the requirements for workers' operation technology, so the welding quality is stable. In manual welding, the welding speed and dry elongation change, so it is difficult to achieve the uniformity of quality.

2.改善了勞動條件。采用機器人焊接,工人只需要做一些簡單的參數(shù)調節(jié)停開機操作,遠離了焊接弧光、煙霧和飛濺等。對于點焊來說,工人無需搬運笨重的手工焊鉗,使工人從高強度的體力勞動中解脫出來。

2. Improved working conditions. With robot welding, workers only need to do some simple parameter adjustment, stop and start operation, which is far away from welding arc, smoke and splash. For spot welding, workers do not need to carry heavy manual welding tongs, so that workers can free themselves from high-intensity physical labor.

3.提高勞動生產(chǎn)率。機器人可24h連續(xù)生產(chǎn)。隨著高速焊接技術的應用,采用機器人焊接,效率提高得更為明顯

3. Improve labor productivity. The robot can produce continuously for 24 hours. With the application of high-speed and high-efficiency welding technology, the efficiency is improved more obviously by using robot welding

4.產(chǎn)品周期明確,容易控制產(chǎn)品產(chǎn)量。機器人的生產(chǎn)節(jié)拍是固定的,因此安排生產(chǎn)計劃非常明確。

4. Clear product cycle and easy to control product output. The production beat of the robot is fixed, so the production plan is very clear.

5.縮短產(chǎn)品改型換代的周期,減小相應的設備投資。可實現(xiàn)小批量產(chǎn)品的焊接自動化。機器人與專機的區(qū)別就是可以通過修改程序以適應不同工件的生產(chǎn)

5. Shorten the cycle of product upgrading and reduce the corresponding equipment investment. It can realize the welding automation of small batch products. The biggest difference between robot and special machine is that it can adapt to the production of different workpieces by modifying the program

以上就是山東數(shù)控焊接設備http://niuniury.com/的相關內容,如果您想要了解更多的相關內容,歡迎聯(lián)系在線客服,我們必將竭誠為您服務。

The above is Shandong CNC welding equipment http://niuniury.com/ If you want to know more about the relevant content, please contact the online customer service, and we will serve you wholeheartedly.

上一篇:全位置焊中自動焊接設備技術性能介紹

下一篇:數(shù)控焊接設備的幾種焊接方法