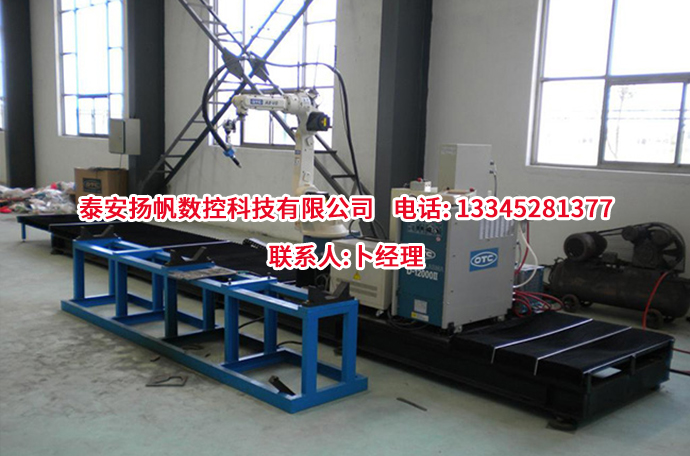

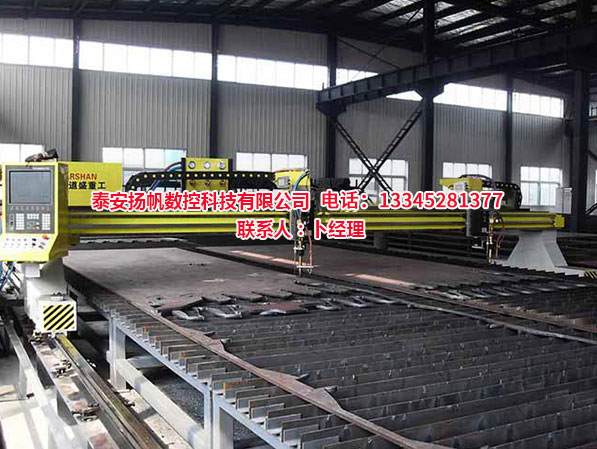

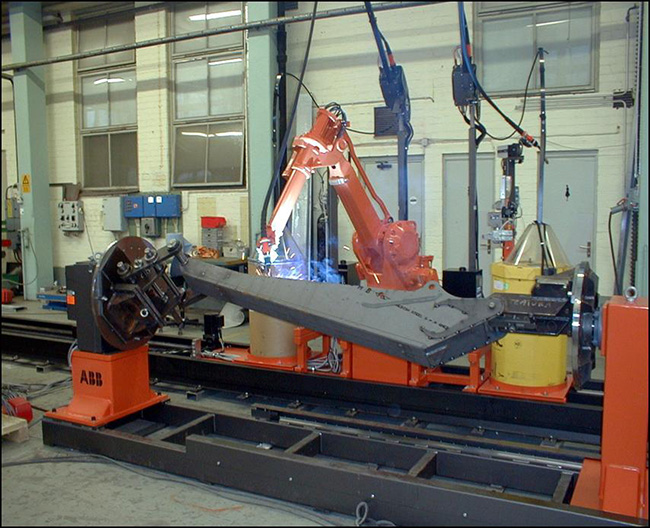

山東焊接專機(jī)共5步操作流程掌握嗎

來(lái)源:http://niuniury.com/ 發(fā)布時(shí)間:2021-12-02 瀏覽次數(shù):0

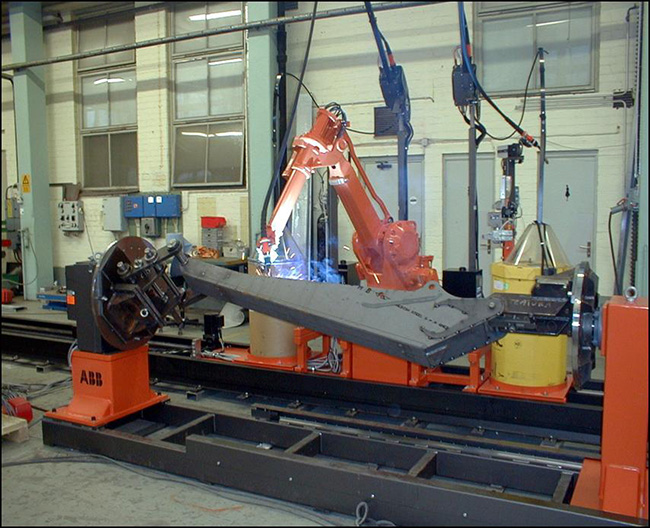

焊接機(jī)操作規(guī)程(焊機(jī)維修規(guī)程)啟動(dòng)后,應(yīng)先空運(yùn)轉(zhuǎn),檢查各傳動(dòng)部件及軸承運(yùn)轉(zhuǎn)正常后,方可操作。

Welding Machine Safety Operating Procedures (welding machine maintenance procedures) start, should first air operation, inspection of the transmission parts and normal operation of bearings, before the operation.

Welding Machine Safety Operating Procedures (welding machine maintenance procedures) start, should first air operation, inspection of the transmission parts and normal operation of bearings, before the operation.

山東焊接專機(jī)共5步操作流程掌握嗎?

Shandong welding machine total 5 Steps Operation Process Control?

Shandong welding machine total 5 Steps Operation Process Control?

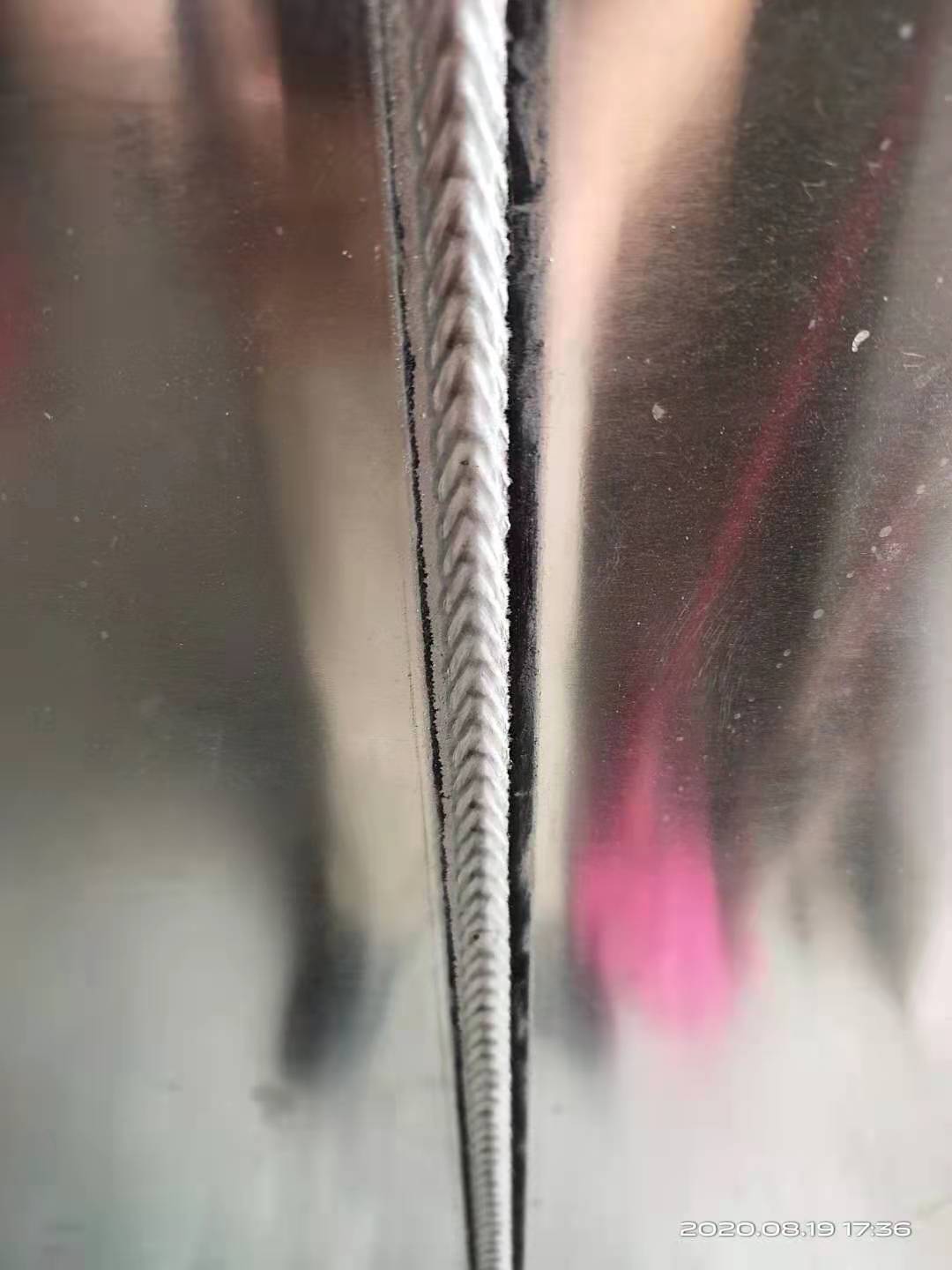

1.起動(dòng)前,必須檢查切刀是否有裂紋,刀架螺栓緊固,防護(hù)罩牢固.再用手轉(zhuǎn)動(dòng)輪齒,檢查齒輪嚙合間隙,調(diào)整刀片間隙.

1. Before starting, must check whether the cutter has cracks, knife frame bolt fastening, shield firm. Turn the gear tooth by hand, check the meshing clearance of the gear and adjust the blade clearance.

1. Before starting, must check whether the cutter has cracks, knife frame bolt fastening, shield firm. Turn the gear tooth by hand, check the meshing clearance of the gear and adjust the blade clearance.

2、當(dāng)機(jī)器沒有達(dá)到正常轉(zhuǎn)速時(shí),山東焊接專機(jī)不能切割,必須使用切割刀的中下位置,握持鋼筋對(duì)著刀口快速送進(jìn),操作者應(yīng)站在固定刀片的一側(cè)用力壓住鋼筋,防止鋼筋末端彈出傷人.嚴(yán)禁用兩手在刀片上夾住鋼筋。

2, when the machine does not reach the normal speed, can not cut, must use the cutting knife in the lower position, holding the steel bar to the edge of the knife, the operator should stand on the side of the fixed blade to press the steel bar, prevent the end of the steel bar from popping out and hurting people. It is strictly forbidden to clamp the rebar on the blade with both hands.

2, when the machine does not reach the normal speed, can not cut, must use the cutting knife in the lower position, holding the steel bar to the edge of the knife, the operator should stand on the side of the fixed blade to press the steel bar, prevent the end of the steel bar from popping out and hurting people. It is strictly forbidden to clamp the rebar on the blade with both hands.

3.起動(dòng)后,應(yīng)先空運(yùn)轉(zhuǎn),檢查各傳動(dòng)部件和軸承運(yùn)轉(zhuǎn)正常后方可使用。

3. After starting, should first air running, check the transmission parts and bearings running properly before use.

3. After starting, should first air running, check the transmission parts and bearings running properly before use.

4.不得剪切直徑和強(qiáng)度超過(guò)機(jī)械銘牌規(guī)定的鋼筋和燒紅的鋼筋.當(dāng)一次切斷多根鋼筋時(shí),其總截?cái)嗝娣e應(yīng)在規(guī)定范圍內(nèi)。

4. Shall Not Shear diameter and strength over the mechanical nameplate provisions of the reinforcement and red-hot reinforcement. When cutting several reinforcing bars at one time, the total cut-off area should be within the prescribed range.

4. Shall Not Shear diameter and strength over the mechanical nameplate provisions of the reinforcement and red-hot reinforcement. When cutting several reinforcing bars at one time, the total cut-off area should be within the prescribed range.

5.送料的工作臺(tái)面應(yīng)和刀片下部保持水平,山東焊接專機(jī)工作臺(tái)長(zhǎng)度可根據(jù)加工材料長(zhǎng)度確定,加工較長(zhǎng)的鋼筋時(shí),應(yīng)專人協(xié)助,聽從操作人員指揮,不得任意推拉。

5. Feed table should be level with the lower part of the blade, table length can be determined according to the length of processing materials. When processing longer steel bar, should be specialized assistance, follow the operator’s command, not arbitrary push and pull.

5. Feed table should be level with the lower part of the blade, table length can be determined according to the length of processing materials. When processing longer steel bar, should be specialized assistance, follow the operator’s command, not arbitrary push and pull.

上一篇:山東數(shù)控焊接設(shè)備管板焊機(jī)的焊接

下一篇:山東數(shù)控焊接設(shè)備的3個(gè)裝置