整個(gè)焊接設(shè)備故障應(yīng)如何檢修

來源:http://niuniury.com/ 發(fā)布時(shí)間:2022-07-28 瀏覽次數(shù):0

目前,應(yīng)用廣泛的焊接設(shè)備有:焊條電弧焊、埋弧焊、鎢極氣體保護(hù)電弧焊、等離子弧焊及對焊等設(shè)備。一樣的是使用時(shí)間長久了就會出現(xiàn)問題,要進(jìn)行維修的話就注意啥?

At present, the widely used welding equipment includes: electrode arc welding, submerged arc welding, tungsten gas shielded arc welding, plasma arc welding and butt welding. The same is that problems will occur after a long time of use. What should we pay attention to if we want to repair?

備未通電時(shí),判斷焊接設(shè)備按鈕、接觸器、熱斷電器元器件以及保險(xiǎn)絲的好壞,從而判定故障的所在。通電試驗(yàn),聽其聲、測參數(shù)、判斷故障,后進(jìn)行維修。

When the equipment is not powered on, judge the quality of the buttons, contactors, thermal breaker components and fuses of the welding equipment, so as to determine the fault. Power on test, listen to its sound, measure parameters, judge faults, and then carry out maintenance.

如果在該文章講述了焊接設(shè)備故障的檢查方法與維修經(jīng)驗(yàn).電焊機(jī)輸入缺相時(shí),測量三相電壓值無法進(jìn)行判別時(shí),就應(yīng)該聽其聲,單獨(dú)測量每一相對地點(diǎn)的電壓,方可判斷哪一相缺損。

If the article describes the inspection methods and maintenance experience of welding equipment faults When the input phase of the electric welding machine is missing, and the measured three-phase voltage value cannot be judged, you should listen to its sound, and measure the voltage of each relative location separately, so as to judge which phase is missing.

染較重的焊接設(shè)備,先對其按鈕、接線點(diǎn)、接觸點(diǎn)進(jìn)行清潔,檢查外部控制鍵是否失靈。許多故障都是由臟污及導(dǎo)電塵埃引起的,一經(jīng)清潔后故障往往會排除。特別是在工程施工現(xiàn)場等環(huán)境比較惡劣的場合。

For heavily dyed welding equipment, first clean its buttons, wiring points and contact points, and check whether the external control keys fail. Many faults are caused by dirt and conductive dust. Once cleaned, the faults are often eliminated. Especially in the construction site and other places with poor environment.

部分的故障往往在整個(gè)焊接設(shè)備故障中占有很高比例,所以先檢修電源輸入部分往往可以事半功倍。然后再按照先外后里、先機(jī)后電、先靜后動的方法檢查焊接設(shè)備的其他輔助部分,如行走、送絲等部位。

Some faults often account for a high proportion of the whole welding equipment faults, so it is often possible to get twice the result with half the effort to overhaul the power input part first. Then check other auxiliary parts of the welding equipment, such as walking, wire feeding and so on, according to the method of "outside first, then inside, machine first, then electricity, static first, then moving".

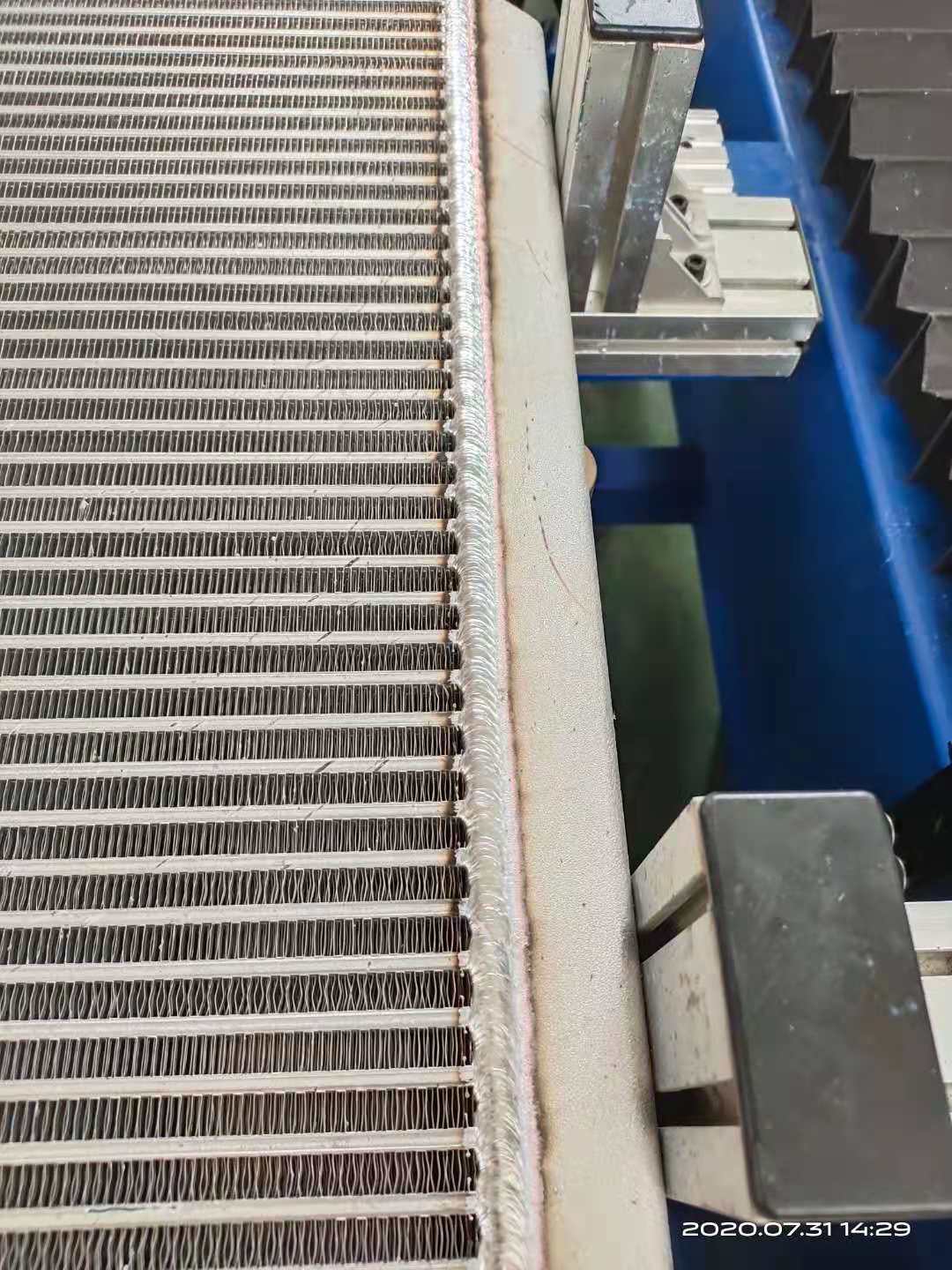

部件和電器元器件、裝配配件質(zhì)量或其他設(shè)備故障所引起的故障,一般占常見故障的50%左右。焊接設(shè)備的特殊故障多為軟故障,要靠經(jīng)驗(yàn)和儀器儀表來測量和維修。

Failures caused by the quality of components and electrical components, assembly accessories or other equipment failures generally account for about 50% of common failures. The special faults of welding equipment are mostly soft faults, which need to be measured and maintained by experience and instruments.

山東自動焊接設(shè)備廠家認(rèn)為現(xiàn)場故障一時(shí)無法判斷,也可以按照產(chǎn)品說明書的聯(lián)系方式咨詢產(chǎn)品生產(chǎn)單位的技術(shù)人員。如點(diǎn)焊、縫焊、凸焊及對焊等設(shè)備的一些內(nèi)部程序,在不清楚、不了解的情況下不要輕易調(diào)整或者改變,否則就會引起更大的麻煩。

Shandong automatic welding equipment manufacturers believe that the on-site fault cannot be judged at the moment, and they can also consult the technical personnel of the product production unit according to the contact information of the product manual. For example, some internal procedures of spot welding, seam welding, projection welding, butt welding and other equipment should not be easily adjusted or changed without knowing or understanding, otherwise it will cause greater trouble.

要急于更換損壞的電氣部件和電器元器件,在確認(rèn)外圍設(shè)備電路正常時(shí),再考慮更換損壞的電器元器件或者檢查印刷電路板。

We should be eager to replace the damaged electrical components and electrical components, and consider replacing the damaged electrical components or checking the printed circuit board after confirming that the peripheral equipment circuit is normal.

于調(diào)試和故障并存的焊接設(shè)備,須先排除故障再進(jìn)行調(diào)試。調(diào)試須在電氣線路完全沒有故障,接線正確(包括接地線)的前提下進(jìn)行。更多相關(guān)內(nèi)容的了解就來我們網(wǎng)站http://niuniury.com看看吧。

For the welding equipment with both debugging and fault, it is necessary to eliminate the fault before debugging. The commissioning must be carried out on the premise that the electrical circuit is completely free of fault and the wiring is correct (including the grounding wire). Come to our website for more information http://niuniury.com Take a look.

上一篇:焊接專機(jī)故障后的直觀法檢查過程步驟

下一篇:配套焊機(jī)對機(jī)械零件使用時(shí)注意事項(xiàng)