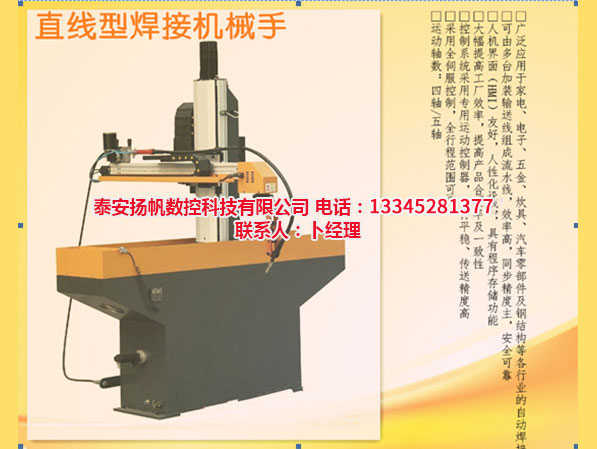

淺談焊接專機(jī)的構(gòu)成要素及系統(tǒng)組成

來源:http://niuniury.com/ 發(fā)布時(shí)間:2022-08-18 瀏覽次數(shù):0

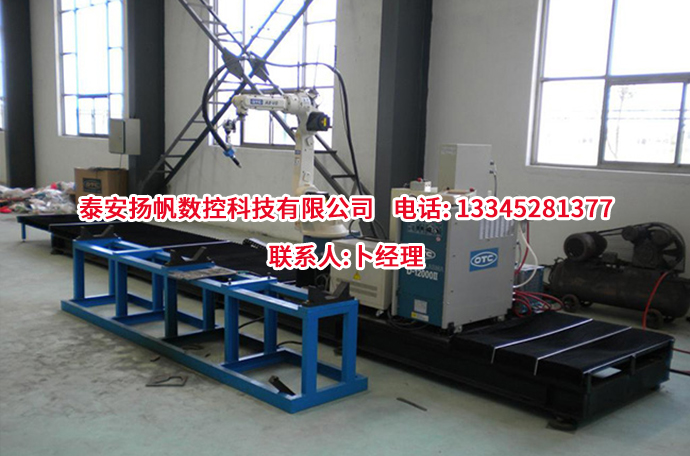

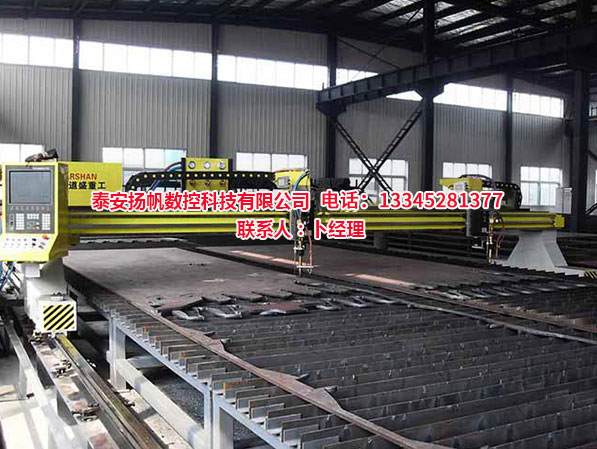

山東焊接專機(jī)是為特定的工件和一定形狀的焊接接頭而專門設(shè)計(jì)的焊接自動(dòng)化設(shè)備。焊接專機(jī)的機(jī)械系統(tǒng)主要由床身機(jī)構(gòu)、工裝夾具及工件輔助支撐機(jī)構(gòu)、焊槍微調(diào)機(jī)構(gòu)、焊接工件或者焊槍移動(dòng)機(jī)構(gòu)等構(gòu)成。

Shandong welding machine is a welding automation equipment specially designed for specific workpieces and welding joints of certain shapes. The mechanical system of the special welding machine is mainly composed of bed mechanism, tooling fixture and workpiece auxiliary support mechanism, welding torch fine adjustment mechanism, welding workpiece or welding torch moving mechanism, etc.

1、床身機(jī)構(gòu):床身主要對(duì)設(shè)備起支撐作用,可以用鑄造件或者焊接件構(gòu)成。由于鑄造件生產(chǎn)周期長,成本高,所以現(xiàn)在基本上采用型材和鋼板焊接后,經(jīng)退火、精加工而成,可以快速制造和成本低,得到大量使用;

1. Bed mechanism: the bed mainly supports the equipment and can be made of cast parts or welded parts. Due to the long production cycle and high cost of cast parts, they are basically made by welding profiles and steel plates, annealing and finishing, which can be rapidly manufactured and low-cost, and are widely used;

2、工裝夾具及輔助支撐機(jī)構(gòu):可以根據(jù)工件的加工面或定位孔,固定工件的相對(duì)位置,可以采用手動(dòng)、氣動(dòng)、電動(dòng)、液壓控制夾具運(yùn)動(dòng),實(shí)現(xiàn)裝夾和定位工件;

2. Fixture and auxiliary support mechanism: the relative position of the workpiece can be fixed according to the machining surface or positioning hole of the workpiece. Manual, pneumatic, electric and hydraulic control of fixture movement can be used to realize clamping and positioning of the workpiece;

3、焊槍微調(diào)機(jī)構(gòu):要焊槍對(duì)準(zhǔn)焊縫,需要對(duì)焊槍的X\Y\Z向進(jìn)行三維調(diào)節(jié),是焊槍的指向?qū)?zhǔn)焊縫,同時(shí)根據(jù)焊接工藝要求,還需實(shí)現(xiàn)各方向的旋轉(zhuǎn)功能;

3. Fine adjustment mechanism of welding gun: to align the welding gun with the weld, three-dimensional adjustment of the X \ y \ Z direction of the welding gun is required. It is the pointing of the welding gun to the weld. At the same time, according to the requirements of the welding process, it also needs to realize the rotation function in all directions;

4、焊接工件或焊槍的移動(dòng)機(jī)構(gòu):要完成直線、圓周或曲線焊縫的焊接,需要焊槍與工件的焊縫的軌跡的相對(duì)運(yùn)動(dòng)才能完成焊接要求。可以選擇焊槍移動(dòng),也可選擇工件運(yùn)動(dòng)。

4. Moving mechanism of welding workpiece or welding torch: to complete the welding of linear, circumferential or curved welds, the relative movement of the weld trajectory of the welding torch and the workpiece is required to complete the welding requirements. You can select the movement of the welding gun or the movement of the workpiece.

此外焊接專機(jī)系統(tǒng)由機(jī)械裝置、供電裝置、控制裝置三大部分組成:

In addition, the special welding machine system is composed of mechanical device, power supply device and control device:

機(jī)械裝置:為了適應(yīng)焊接工藝要求,加壓機(jī)構(gòu)(焊鉗)采用了雙行程快速氣壓傳動(dòng)機(jī)構(gòu),通過切換行程控制手柄改變焊鉗開口度,可分為大開和小開來滿足焊接操作要求。

Mechanical device: in order to meet the requirements of welding process, the pressurizing mechanism (welding tongs) adopts a double stroke fast pneumatic transmission mechanism. The opening of the welding tongs can be changed by switching the stroke control handle, which can be divided into large opening and small opening to meet the requirements of welding operation.

供電裝置:主電力電路由電阻焊變壓器、可控硅單元、主電力開關(guān)、焊接回路等組成。目前,我們采用的焊接設(shè)備是功率200kVA、次級(jí)輸出電壓20V的單相工頻交流電阻焊機(jī)。

Power supply device: the main power circuit is composed of resistance welding transformer, thyristor unit, main power switch, welding circuit, etc. At present, the welding equipment we use is a single-phase power frequency AC resistance welding machine with a power of 200KVA and a secondary output voltage of 20V.

控制裝置:控制裝置主要提供信號(hào)控制電阻焊機(jī)動(dòng)作接通和切斷焊接電流,控制焊接電流值,進(jìn)行故障監(jiān)測(cè)和處理。

Control device: the control device mainly provides signals to control the resistance welding machine to switch on and off the welding current, control the welding current value, and conduct fault monitoring and treatment.

當(dāng)然要注意,您在采購或者定制該設(shè)備的時(shí)候,要慎重考慮設(shè)計(jì)和是否合理,以避免買到存在嚴(yán)重的質(zhì)量隱患的專機(jī)。有關(guān)的注意事項(xiàng)就來我們網(wǎng)站http://niuniury.com咨詢吧。

Of course, it should be noted that when purchasing or customizing the equipment, you should carefully consider whether the design and price are reasonable, so as to avoid buying a special plane with serious quality risks. Please come to our website for relevant precautions http://niuniury.com Consult.

上一篇:數(shù)控焊接設(shè)備選購的三個(gè)注意點(diǎn)

下一篇:使用直縫直縫自動(dòng)焊接專機(jī)需要注意的問題