焊接專機(jī)的四點(diǎn)安裝調(diào)試事項(xiàng)

來源:http://niuniury.com/ 發(fā)布時(shí)間:2022-10-27 瀏覽次數(shù):0

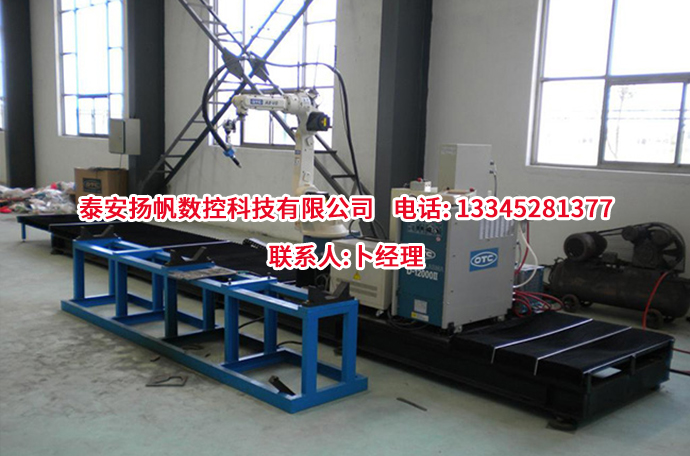

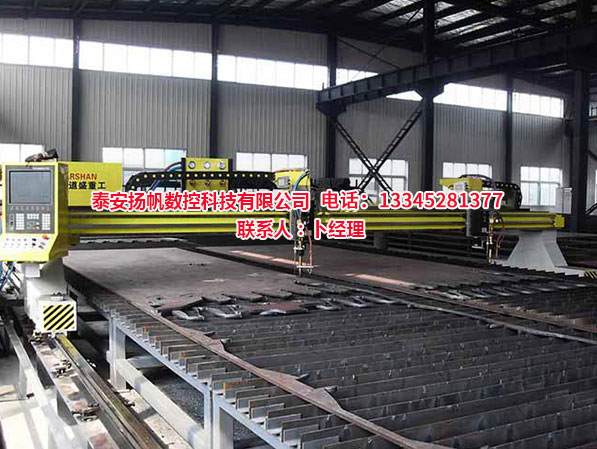

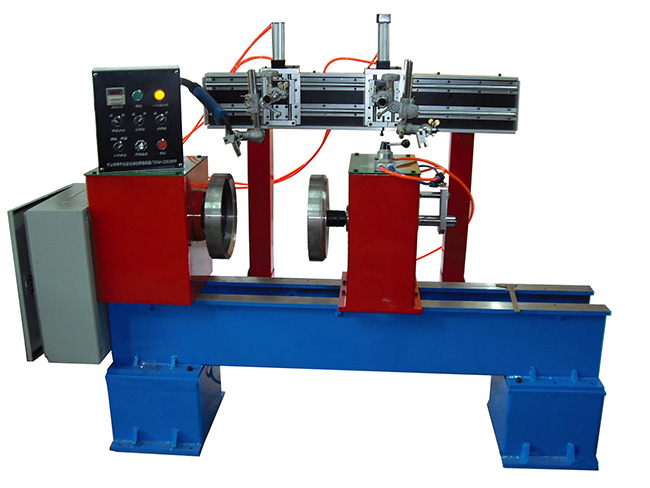

焊接專機(jī)的機(jī)械系統(tǒng)主要由床身機(jī)構(gòu)、工裝夾具及工件輔助支撐機(jī)構(gòu)、焊槍微調(diào)機(jī)構(gòu)、焊接工件或者焊槍移動(dòng)機(jī)構(gòu)等構(gòu)成。下面山東焊接專機(jī)廠家分享一下焊接專機(jī)的安裝調(diào)試事項(xiàng)。

The mechanical system of the special welding machine is mainly composed of the machine body mechanism, tooling fixture and workpiece auxiliary support mechanism, welding gun trimming mechanism, welding workpiece or welding gun moving mechanism, etc. Next, Shandong welding machine manufacturer will share the installation and commissioning of the welding machine.

1、設(shè)備終驗(yàn)收合格后保修12個(gè)月,在質(zhì)保期期間,將提供各種技術(shù)服務(wù)。

1. The equipment shall be guaranteed for 12 months after final acceptance. During the warranty period, various technical services will be provided free of charge.

2、供方將建立詳細(xì)用戶檔案,在質(zhì)保期期滿后,依然提供廣泛而優(yōu)惠的技術(shù)支持,以及技術(shù)咨詢和備品備件的供應(yīng),費(fèi)用雙方協(xié)商確定。

2. The Supplier will establish detailed user files, and after the expiration of the warranty period, it will still provide extensive and preferential technical support, as well as technical consultation and supply of spare parts. The cost will be determined by both parties through consultation.

3、供方將派出技術(shù),負(fù)責(zé)設(shè)備在業(yè)主現(xiàn)場所在地的設(shè)備安裝、調(diào)試以及試運(yùn)行,確保用戶人員能正確使用以及試運(yùn)行,生產(chǎn)出合格產(chǎn)品。

3. The Supplier will send technical experts to be responsible for the installation, commissioning and trial operation of the equipment at the Owner's site, so as to ensure that the user's personnel can correctly use and test run the equipment and produce qualified products.

4、供方在需方完成現(xiàn)場安裝、調(diào)試以及試運(yùn)行后,將對用戶有關(guān)技術(shù)、操作、維修人員進(jìn)行系統(tǒng)技術(shù)培訓(xùn)。

4. After the Demander completes on-site installation, commissioning and trial operation, the Supplier will provide free technical training for users' relevant technical, operation and maintenance personnel.

安裝注意事項(xiàng)

Installation precautions

1、整機(jī)應(yīng)可靠接地。

1. The whole machine shall be reliably grounded.

2、安裝時(shí)注意升降、伸縮行程開關(guān)觸發(fā)動(dòng)作可靠。

2. During installation, pay attention to the reliable triggering action of lifting and retracting travel switches.

3、橫臂安裝完成后,應(yīng)先手動(dòng)推動(dòng)橫臂來回試車,確保手動(dòng)推時(shí)不費(fèi)力方可(如果費(fèi)力調(diào)整偏心輪的加緊力度)。

3. After the installation of the cross arm is completed, the cross arm shall be manually pushed back and forth for test run to ensure that the manual pushing is effortless (if it is difficult to adjust the tightening force of the eccentric).

4、橫臂調(diào)試完成后安裝橫臂電機(jī)減速機(jī),調(diào)整齒輪與齒條的嚙合間隙,調(diào)整后固定即可。

4. After the commissioning of the cross arm is completed, install the cross arm motor reducer, adjust the meshing clearance between the gear and the rack, and fix it after adjustment.

5、在安裝鏈條與橫臂平衡塊之間聯(lián)接時(shí),須在橫臂升位,平衡鐵與底座保持一定間隙,橫臂放限位時(shí),平衡鐵與頂板之間保持一定間隙。

5. When installing the connection between the chain and the cross arm balance block, the cross arm must be lifted to the position, the balance iron and the base must maintain a certain clearance, and when the cross arm is placed to the limit, the balance iron and the top plate must maintain a certain clearance.

焊接專機(jī)的四點(diǎn)安裝調(diào)試事項(xiàng)就講解到這里了,您對此有什么需求可以隨時(shí)來我們網(wǎng)站http://niuniury.com進(jìn)行咨詢!

This is the end of the four point installation and debugging of the welding machine. If you have any needs, you can come to our website at any time http://niuniury.com Consult!

上一篇:采購數(shù)控焊接設(shè)備時(shí)可參考這三點(diǎn)

下一篇:自動(dòng)焊接專機(jī)的使用三大類介紹