數(shù)控焊接設(shè)備工藝的一些要點總結(jié)

來源:http://niuniury.com/ 發(fā)布時間:2023-06-17 瀏覽次數(shù):0

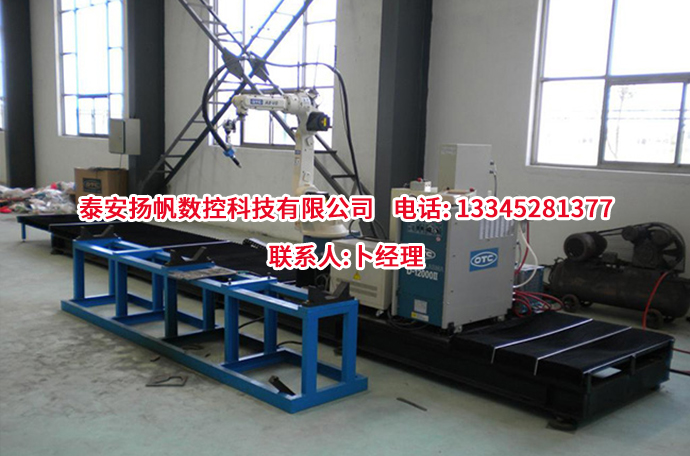

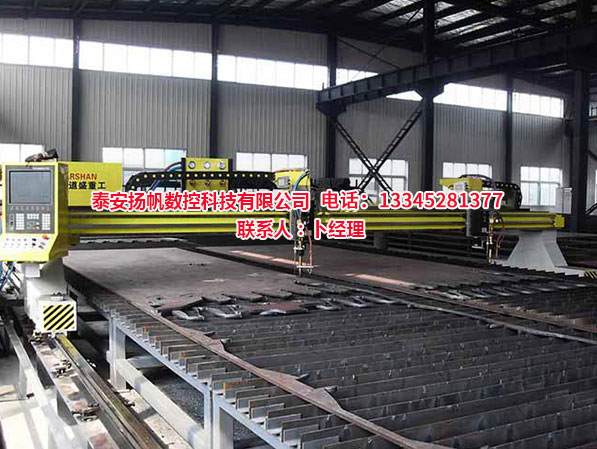

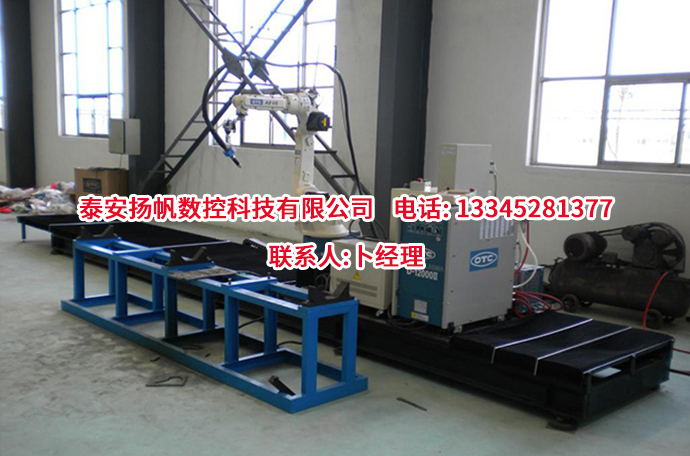

在數(shù)控焊接設(shè)備行業(yè)中,除了機器的質(zhì)量外,工藝也是關(guān)重要的。以下是山東數(shù)控焊接設(shè)備工藝的一些要點總結(jié)。

In the CNC welding equipment industry, in addition to the quality of the machine, the process is also crucial. The following is a summary of some key points of Shandong CNC welding equipment technology.

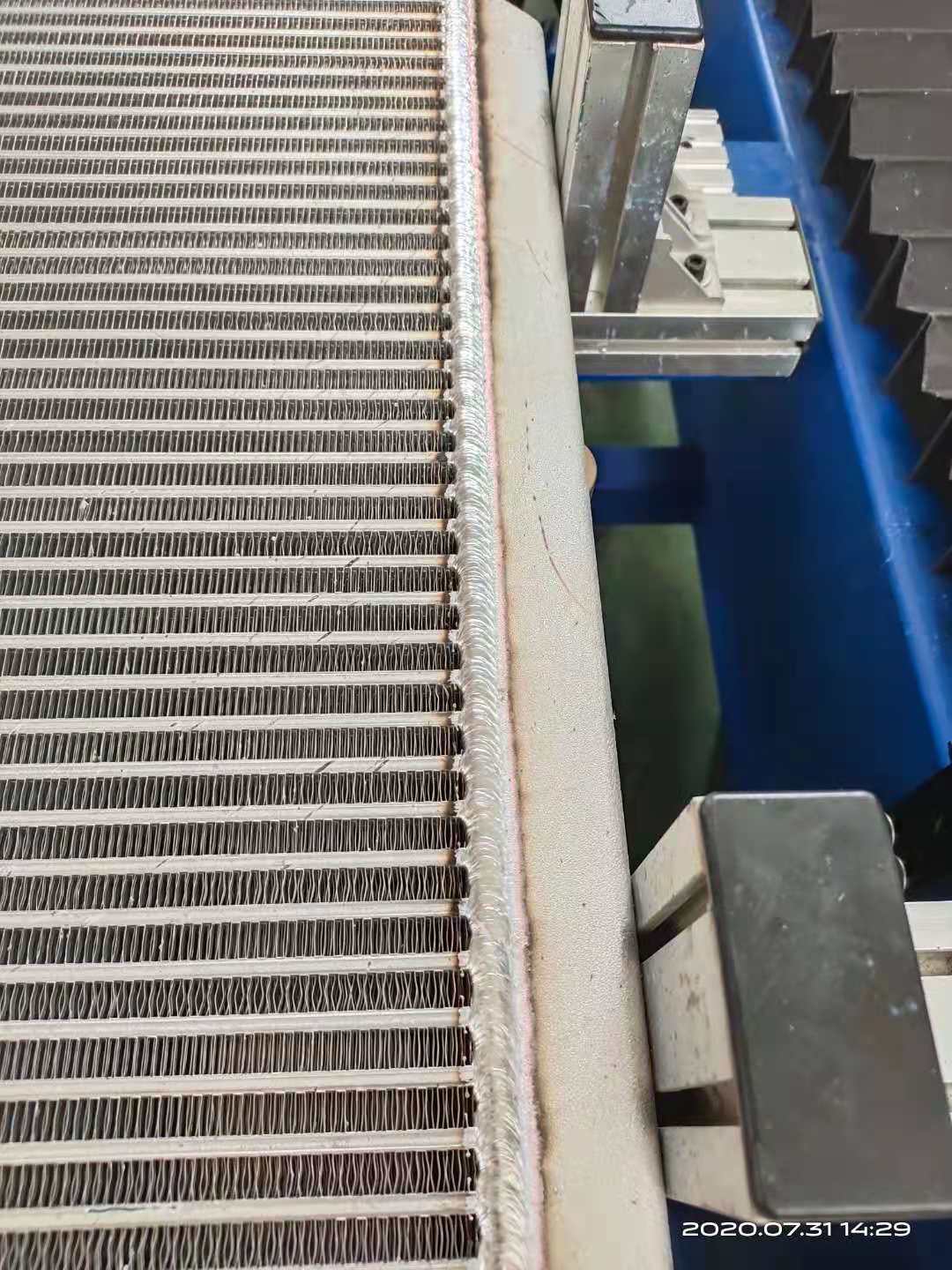

焊接前應(yīng)該做好準(zhǔn)備工作,包括檢查機器狀態(tài)和準(zhǔn)備工件和焊材。焊接時應(yīng)注意設(shè)置合理的焊接參數(shù),以確保焊接質(zhì)量。在焊接方向上,應(yīng)遵循從“薄到厚、從小到大”的原則,以確保焊縫的質(zhì)量和連接度。

Before welding, preparations should be made, including checking the machine status and preparing workpieces and welding materials. When welding, attention should be paid to setting reasonable welding parameters to ensure welding quality. In the welding direction, the principle of "thin to thick, small to large" should be followed to ensure the quality and connectivity of the weld seam.

此外,焊接應(yīng)保證實時監(jiān)測和記錄焊接過程中的溫度和電流等參數(shù),以便后期研究和分析。其次,焊接過程中需特別注意。焊接區(qū)域應(yīng)設(shè)立警戒線,并保持良好的通風(fēng)和換氣,以避免有害氣體的積聚。

In addition, welding should ensure real-time monitoring and recording of parameters such as temperature and current during the welding process for later research and analysis. Secondly, special attention should be paid to safety during the welding process. Warning lines should be set up in the welding area and good ventilation and ventilation should be maintained to avoid the accumulation of harmful gases.

在焊接區(qū)域附近,必須使用防護設(shè)施,包括防護鏡、手套、面罩和防護靴等。此外,操作人員應(yīng)接受培訓(xùn),并通過考核和認(rèn)證,以確保其掌握了正確的操作技能和知識。

In the vicinity of the welding area, protective facilities must be used, including protective goggles, safety gloves, masks, and protective boots. In addition, operators should receive training and pass assessments and certifications to ensure that they have mastered the correct operating skills and safety knowledge.

應(yīng)對數(shù)控焊接設(shè)備進行常規(guī)維護和保養(yǎng),以確保其操作效果和壽命。維護過程應(yīng)包括清潔、潤滑和更換損壞的部件等。應(yīng)定期進行設(shè)備檢查和保養(yǎng),以確保其完好,避免意外損壞和故障。

Routine maintenance and upkeep should be carried out on CNC welding equipment to ensure its operational effectiveness and lifespan. The maintenance process should include cleaning, lubrication, and replacing damaged components. Regular equipment inspection and maintenance should be carried out to ensure its integrity and avoid accidental damage and malfunctions.

如果發(fā)現(xiàn)設(shè)備故障或異常,應(yīng)立即確保,進行必要的修理和更換??傊瑪?shù)控焊接設(shè)備工藝對焊接質(zhì)量、操作和設(shè)備壽命都具有重要影響。

If equipment malfunctions or abnormalities are found, safety should be immediately ensured and necessary repairs and replacements should be made. In summary, the process of CNC welding equipment has a significant impact on welding quality, operational safety, and equipment life.

操作人員應(yīng)掌握這些工藝要點,并一直保持警惕和注意力,以確保操作過程的成功和。更多相關(guān)事項就來我們網(wǎng)站http://niuniury.com咨詢!

Operators should master these process points and remain vigilant and attentive at all times to ensure the success and safety of the operation process. For more related matters, come to our website http://niuniury.com consulting service