數(shù)控焊接設(shè)備的日常三大檢查使用

來源:http://niuniury.com/ 發(fā)布時(shí)間:2022-11-29 瀏覽次數(shù):0

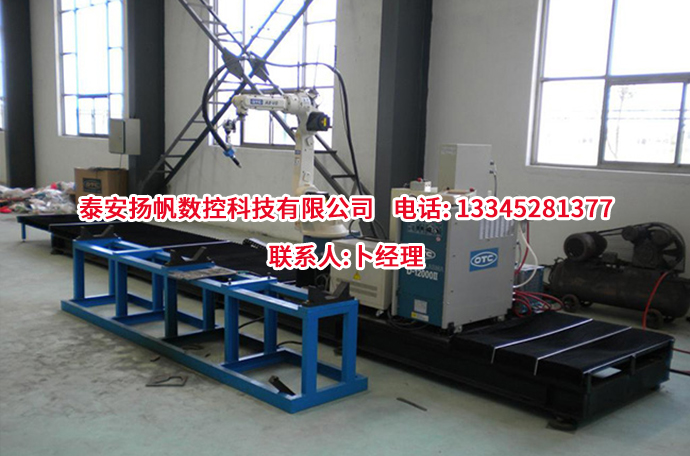

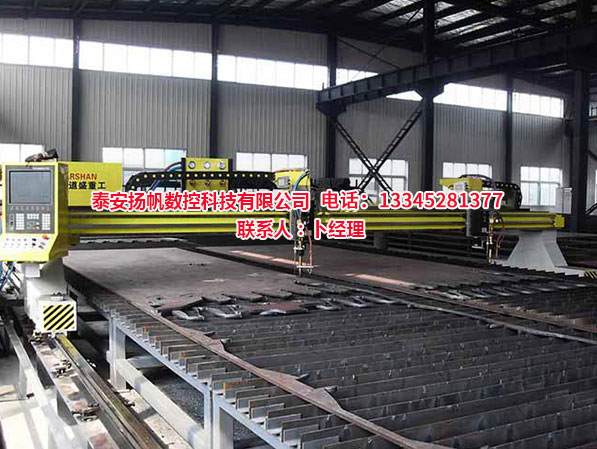

所謂預(yù)防性維修,就是要注意把有可能造成設(shè)備故障和出了故障后難以解決的因素排除在故障發(fā)生之前,盡量減少或延緩數(shù)控設(shè)備的故障。下面山東數(shù)控焊接設(shè)備廠家來講講數(shù)控焊接設(shè)備的日常三大檢查使用。

The so-called preventive maintenance is to eliminate the factors that may cause equipment failure and are difficult to solve after the failure before the failure occurs, so as to reduce or delay the failure of NC equipment as much as possible. Next, Shandong CNC welding equipment manufacturer will talk about the daily three major inspections of CNC welding equipment.

1.正確使用設(shè)備

1. Use the equipment correctly

數(shù)控設(shè)備的正確使用是減少設(shè)備故障、延長使用壽命的關(guān)鍵,它在預(yù)防性維修中占有很重要的地位。據(jù)統(tǒng)計(jì),有三分之一的故障是人為造成的,且-般性維護(hù)(如注油、清洗、檢查等)是由操作者進(jìn)行的,解決的方法是:強(qiáng)調(diào)設(shè)備管理、使用和維護(hù)意識(shí),加強(qiáng)業(yè)務(wù)、技術(shù)培訓(xùn),提高操作人員素質(zhì),使他們盡快掌握數(shù)控機(jī)床的性能,嚴(yán)格執(zhí)行設(shè)備操作規(guī)程和維護(hù)保養(yǎng)規(guī)程,保證設(shè)備運(yùn)行在合理的工作狀態(tài)之中。

The correct use of NC equipment is the key to reduce equipment failures and extend service life, and it plays an important role in preventive maintenance. According to statistics, one-third of the failures are caused by human beings, and general maintenance (such as oil injection, cleaning, inspection, etc.) is carried out by operators. The solution is to emphasize the awareness of equipment management, use and maintenance, strengthen business and technical training, improve the quality of operators, so that they can master the performance of CNC machine tools as soon as possible, strictly implement the equipment operation procedures and maintenance procedures, and ensure that the equipment operates in a reasonable working state.

2.操作者日常檢查

2. Daily inspection of operators

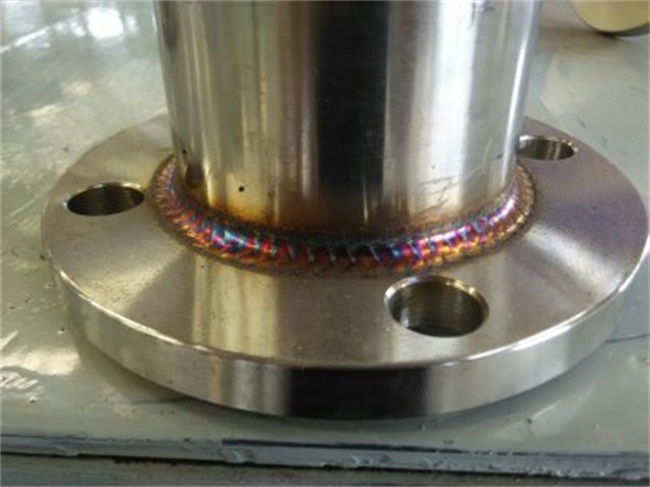

操作者是數(shù)控設(shè)備的直接用戶,為了保證數(shù)控設(shè)備的正常運(yùn)行,要求數(shù)控操作者每天應(yīng)該執(zhí)行以下各項(xiàng):檢查所有的防護(hù)板、殼和門操作是否適當(dāng)、在整個(gè)行程中步進(jìn)每一個(gè)軸,觀察運(yùn)行是否平滑、確保所有軸的限位開關(guān)正常工作并調(diào)整到相應(yīng)的限位位置、檢查導(dǎo)軌是否有劃傷或過度磨損的跡象、檢查導(dǎo)軌清潔器沒有被損壞、觸摸導(dǎo)軌檢查潤滑是否適當(dāng)。

The operator is the direct user of the CNC equipment. To ensure the normal operation of the CNC equipment, the CNC operator is required to perform the following items every day: check whether all protective plates, shells and doors are properly operated, step each axis in the whole stroke, observe whether the operation is smooth, ensure that the limit switches of all axes work normally and adjust to the corresponding limit positions, check whether the guide rails are scratched or excessively worn Check that the guide rail cleaner is not damaged. Touch the guide rail to check whether the lubrication is proper.

3.巡回檢查設(shè)備

3. Patrol inspection equipment

根據(jù)數(shù)控設(shè)備的性、復(fù)雜性和智能化高的特點(diǎn),使得它的維護(hù)、保養(yǎng)工作比普通設(shè)備復(fù)雜且要求搞的多。維修人員應(yīng)通過經(jīng)常性的巡回檢查,如CNC系統(tǒng)的排風(fēng)扇運(yùn)行情況,機(jī)柜、電機(jī)是否發(fā)熱,是否有異常聲音或有異味,壓勵(lì)表指示是否正常,各管路及接頭有無泄漏、潤滑狀況是否良好等,

According to the progressiveness, complex and intelligent characteristics of CNC equipment, its maintenance is more complex and requires more than ordinary equipment. The maintenance personnel shall conduct regular patrol inspection, such as the operation of the exhaust fan of the CNC system, whether the cabinet and motor are hot, whether there is abnormal sound or smell, whether the indication of the piezometer is normal, whether there is leakage in all pipelines and joints, and whether the lubrication is good,

積極做好故障和事故預(yù)防,若發(fā)現(xiàn)異常應(yīng)及時(shí)解決,這樣做才有可能把故障消滅在萌牙狀態(tài)之中,從而可以減少可避免的損失。

Actively prevent failures and accidents, and timely solve any abnormalities found, so as to eliminate the failure in the embryonic state and reduce avoidable losses.

數(shù)控焊接設(shè)備的日常三大檢查使用相關(guān)內(nèi)容就到這里了,您對(duì)此有什么相關(guān)的咨詢或者相關(guān)的需求,就來我們網(wǎng)站http://niuniury.com進(jìn)行留言聯(lián)系吧!

This is the end of the daily three major inspections of CNC welding equipment. If you have any related inquiries or needs, please come to our website http://niuniury.com Leave a message to contact!

上一篇:自動(dòng)焊接專機(jī)的分類以及使用注意

下一篇:自動(dòng)焊接設(shè)備焊出來發(fā)黑是什么原因