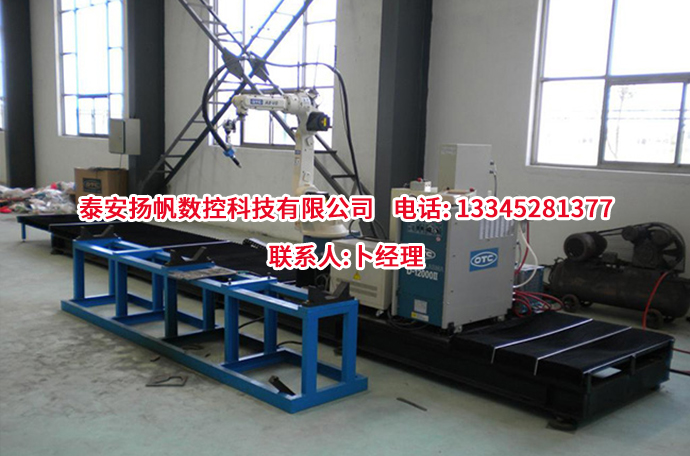

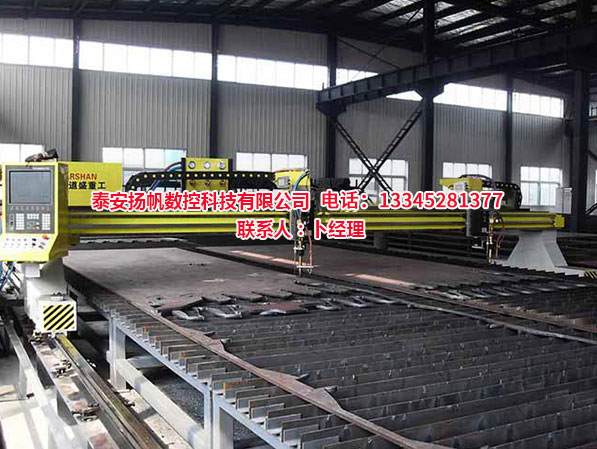

自動焊接設備的好作用以及操作事項

來源:http://niuniury.com/ 發(fā)布時間:2023-03-28 瀏覽次數:0

自動焊接設備是一種高能效、精確、的焊接設備,具有怎樣的作用呢?要怎么的進行操作呢?下面山東自動焊接設備廠家為您分析:

Automatic welding equipment is a highly energy efficient, accurate, and safe welding equipment. What role does it play? How to operate safely? The following is an analysis by Shandong automatic welding equipment manufacturer:

提高焊接質量:自動焊接設備能夠進行精確的焊接控制,避免焊接過程中出現偏差和質量問題,從而提高焊接質量。

Improve welding quality: Automatic welding equipment can perform accurate welding control to avoid deviations and quality issues during the welding process, thereby improving welding quality.

提高生產效率:自動焊接設備能夠進行連續(xù)不斷的焊接作業(yè),避免了人工焊接的繁瑣和低效,從而大大提高了生產效率。

Improve production efficiency: Automatic welding equipment can perform continuous welding operations, avoiding the cumbersome and inefficient manual welding, thereby greatly improving production efficiency.

降低勞動強度:自動焊接設備能夠減少人工焊接的勞動強度,避免了工人在高溫、高壓、高噪音等環(huán)境下工作的危險和不適。

Reducing labor intensity: Automatic welding equipment can reduce the labor intensity of manual welding, avoiding the dangers and discomfort of workers working in high temperature, high pressure, high noise, and other environments.

提高性:自動焊接設備能夠避免工人在焊接過程中接觸高溫、高壓、有毒氣體等危險物質,從而提高了工作性。

Improve safety: Automatic welding equipment can prevent workers from contacting hazardous substances such as high temperature, high pressure, and toxic gases during the welding process, thereby improving work safety.

自動焊接設備的操作事項如下:

The operation of automatic welding equipment is as follows:

在操作前需要對設備進行檢查和維護,確保設備處于良好的工作狀態(tài)。

Before operation, it is necessary to inspect and maintain the equipment to ensure that it is in good working condition.

操作人員需要經過的培訓和操作指導,熟悉設備的使用方法和注意事項。

Operators need to undergo professional training and operation guidance, and be familiar with the use methods and precautions of the equipment.

在操作過程中需要注意操作規(guī)范和,避免誤操作和事故發(fā)生。

During operation, it is necessary to pay attention to operating specifications and safety to avoid misoperation and accidents.

操作人員需要定期對設備進行清潔和維護,保持設備的良好狀態(tài)。

Operators need to regularly clean and maintain the equipment to maintain it in good condition.

在操作過程中需要注意設備的運行情況,及時發(fā)現和處理故障和問題。

During the operation process, it is necessary to pay attention to the operation of the equipment, and timely detect and handle faults and problems.

自動焊接設備具有提高焊接質量、生產效率和性的作用,操作人員需要經過培訓和維護設備的操作規(guī)范和,以確保設備的正常運行和工作效率。您有相關的疑惑或者需求,就來我們網站http://niuniury.com咨詢吧!

Automatic welding equipment plays a role in improving welding quality, production efficiency, and safety. Operators need to undergo professional training and maintain the equipment's operational specifications and safety to ensure the normal operation and efficiency of the equipment. If you have any doubts or needs, please come to our website http://niuniury.com Consult!

上一篇:操作人員應注意自動焊接設備的使用

下一篇:焊接專機的零部件檢查