自動(dòng)焊接專(zhuān)機(jī)的概述以及分類(lèi)情況

來(lái)源:http://niuniury.com/ 發(fā)布時(shí)間:2022-09-24 瀏覽次數(shù):0

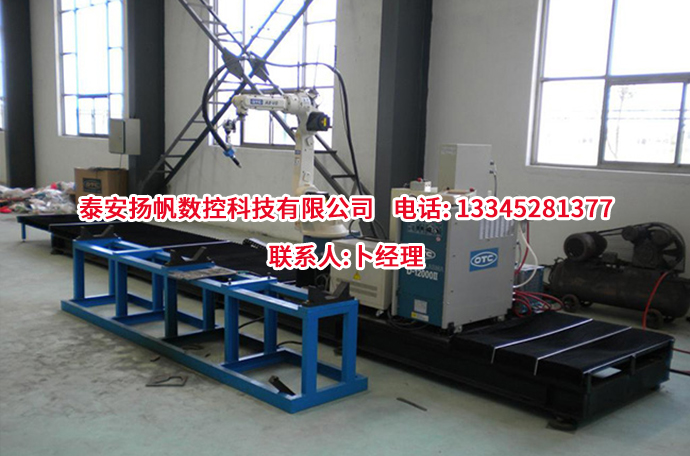

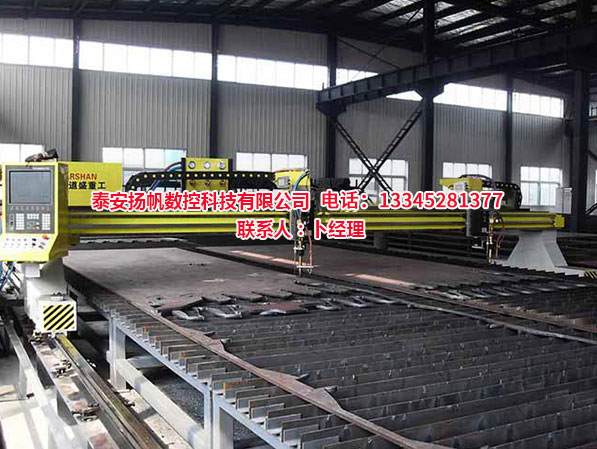

如今人們對(duì)產(chǎn)品的質(zhì)量有了更高的要求,焊接的質(zhì)量以及美觀程度也得到了更大的重視。所以在現(xiàn)代工業(yè)中越來(lái)越多的,自動(dòng)焊接專(zhuān)機(jī)開(kāi)始在焊接過(guò)程中使用。今天山東焊接專(zhuān)機(jī)廠家就來(lái)講講自動(dòng)焊接專(zhuān)機(jī)的概述以及分類(lèi)情況。

Nowadays, people have higher requirements for the quality of products, and more attention has been paid to the quality and aesthetic degree of welding. Therefore, in modern industry, more and more automatic welding machines are used in the welding process. Today, Shandong welding machine manufacturer will talk about the overview and classification of automatic welding machine.

自動(dòng)焊接專(zhuān)機(jī)的概述

Overview of automatic welding machine

自動(dòng)焊接專(zhuān)機(jī)是為特定的工件和一定形狀的焊接接頭而為此專(zhuān)門(mén)設(shè)計(jì)的一種焊接自動(dòng)化的設(shè)備。它主要是由焊接電源,焊接接頭焊件移動(dòng)和輔助裝置幾部分構(gòu)成的。它主要工作原理是通過(guò)電氣控制、氣動(dòng)控制和液壓控制等一系列技術(shù),來(lái)實(shí)現(xiàn)對(duì)電動(dòng)機(jī)、氣動(dòng)、液壓執(zhí)行元件的旋轉(zhuǎn)或移動(dòng)來(lái)實(shí)現(xiàn)焊接工作。

The automatic welding machine is a kind of automatic welding equipment specially designed for specific workpieces and welding joints of certain shapes. The utility model is mainly composed of a welding power source, a welding joint weldment movement and an auxiliary device. Its main working principle is to realize the welding work by rotating or moving the motor, pneumatic and hydraulic actuators through a series of technologies such as electrical control, pneumatic control and hydraulic control.

自動(dòng)焊接專(zhuān)機(jī)的分類(lèi)

Classification of automatic welding machines

自動(dòng)焊接專(zhuān)機(jī)可以分為開(kāi)環(huán)控制型、自適應(yīng)控制型和智能化三種類(lèi)型。開(kāi)環(huán)控制型的結(jié)構(gòu)比較簡(jiǎn)單,技術(shù)要求和成本相對(duì)來(lái)說(shuō)比較低一點(diǎn),因此開(kāi)環(huán)控制型使用量比較大一點(diǎn)。

The automatic welding machine can be divided into three types: open-loop control type, adaptive control type and intelligent type. The structure of the open-loop control type is relatively simple, and the technical requirements and cost are relatively low, so the use of the open-loop control type is relatively large.

自適應(yīng)控制,顧名思義,它的自動(dòng)化程度比較高,它配備了傳感器和電子檢測(cè)線(xiàn)路,可以自動(dòng)跟蹤焊縫。智能化的自動(dòng)焊接專(zhuān)機(jī)是利用各類(lèi)的傳感元件。

Adaptive control, as the name implies, is highly automated. It is equipped with sensors and electronic detection lines, which can automatically track the weld seam. The intelligent automatic welding machine uses various advanced sensing elements.

通常情況下,操作人員只要在人機(jī)界面輸入相關(guān)參數(shù),就可以完成自動(dòng)焊接。但是這種設(shè)備的成本比較高,而且在實(shí)際中存在著很多影響焊接質(zhì)量的因素,所以在實(shí)際中的應(yīng)用比較少。

In general, the operator can complete automatic welding as long as he/she inputs relevant parameters in the man-machine interface. However, the cost of this kind of equipment is relatively high, and there are many factors that affect the welding quality in practice, so the application in practice is relatively small.

此外在使用自動(dòng)焊接專(zhuān)機(jī)時(shí)要注意定期清理,避免沾上粘土、油污等雜質(zhì);要注意的是設(shè)備要保持平穩(wěn),以免精度受到影響;在操作的時(shí)候要注意觀察焊接的情況,以免發(fā)生意外。更多事項(xiàng)就來(lái)我們網(wǎng)站http://niuniury.com進(jìn)行咨詢(xún)吧!

In addition, pay attention to regular cleaning when using the automatic welding machine to avoid clay, oil and other impurities; It should be noted that the equipment should be kept stable so as not to affect the accuracy; Pay attention to the welding during operation to avoid accidents. Come to our website for more information http://niuniury.com Consult!

上一篇:數(shù)控焊接設(shè)備選購(gòu)時(shí)考慮三方面

下一篇:自動(dòng)焊接設(shè)備的操作以及維護(hù)