關(guān)于自動焊接設(shè)備的基本構(gòu)成

來源:http://niuniury.com/ 發(fā)布時間:2022-11-24 瀏覽次數(shù):0

在機(jī)械行業(yè)中,一般都會用到自動焊接設(shè)備,對于剛接觸這一行業(yè)的人來說,對設(shè)備還尚不熟悉,今天山東自動焊接設(shè)備廠家就為大家簡單介紹下,設(shè)備的基本構(gòu)成和特點(diǎn)等內(nèi)容,希望剛?cè)胄械男率帜苡玫健?/div>

In the mechanical industry, automatic welding equipment is generally used. For those who are new to this industry, they are still unfamiliar with the equipment. Today, Shandong automatic welding equipment manufacturer will give you a brief introduction to the basic composition and characteristics of the equipment. I hope that novices can use it.

1、焊接電源。其輸出功率和焊接特性應(yīng)與擬用的焊接工藝方法相匹配,并裝有與主控制器相連接的接口。

1. Welding power source. Its output power and welding characteristics shall match the proposed welding process method and be equipped with an interface connected to the main controller.

2、送絲機(jī)及其控制與調(diào)速系統(tǒng)。對于送絲速度控制精度要求較高的送絲機(jī),其控制電路應(yīng)加測速反饋。

2. Wire feeder and its control and speed regulation system. For wire feeder with high control accuracy of wire feeding speed, speed measurement feedback shall be added to its control circuit.

3、主控制部分,亦稱系統(tǒng)控制器。主要用于各組成部分的聯(lián)動控制,程序的控制,主要參數(shù)的設(shè)定,調(diào)整和顯示。必要時可擴(kuò)展故障診斷和人機(jī)對話等控制功能。

3. The main control part is also called the system controller. It is mainly used for linkage control of various components, program control, setting, adjustment and display of main parameters. If necessary, control functions such as fault diagnosis and man-machine conversation can be extended.

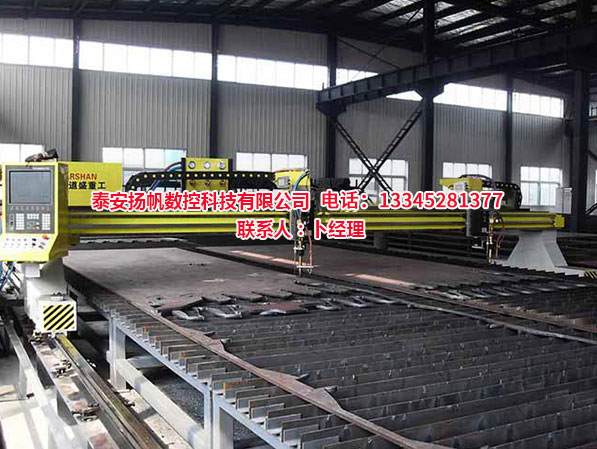

4、焊件移動或變位機(jī)構(gòu)。如焊接滾輪架,頭尾架翻轉(zhuǎn)機(jī),回轉(zhuǎn)平臺和變位機(jī)等,精細(xì)型的移動變位機(jī)構(gòu)應(yīng)配伺服電動機(jī)驅(qū)動。

4. Weldment movement or displacement mechanism. For example, welding roller frame, head and tail frame turnover machine, rotary platform and positioner, etc., fine mobile positioner shall be driven by servo motor.

5、焊頭導(dǎo)向或跟蹤機(jī)構(gòu)?;鹤詣涌刂破?,焊槍橫擺器和監(jiān)控系統(tǒng)。

5. Welding head guide or tracking mechanism. Automatic arc voltage controller, welding torch sway device and monitoring system.

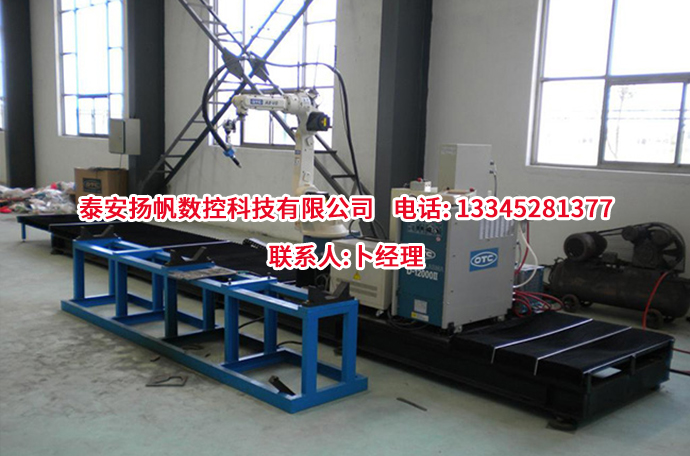

6、焊接機(jī)器人,又稱機(jī)械手臂,是自動化焊接設(shè)備的重要組成部分,其主要工作包括:焊接、切割、熱噴涂、搬運(yùn)等。

6. Welding robot, also known as robot arm, is an important part of automatic welding equipment. Its main work includes: welding, cutting, thermal spraying, handling, etc.

7、計(jì)算機(jī)軟件。設(shè)備中常用的計(jì)算機(jī)軟件有編程軟件,功能軟件,工藝方法軟件和系統(tǒng)等。

7. Computer software. The computer software commonly used in the equipment includes programming software, functional software, process method software and expert system.

8、輔助裝置,如送絲系統(tǒng),循環(huán)水冷系統(tǒng)、焊劑回收輸送裝置、焊絲支架、電纜軟管及拖鏈機(jī)構(gòu)結(jié)構(gòu)設(shè)計(jì)電氣控制設(shè)計(jì)三大部分。

8. Auxiliary devices, such as wire feeding system, circulating water cooling system, flux recycling and conveying device, welding wire support, cable hose and drag chain mechanism, are mainly designed for electrical control.

操作人員在使用自動焊接設(shè)備的時候,要提前了解設(shè)備的相關(guān)特點(diǎn)、組成等功能,以免在后期使用中出現(xiàn)問題,大家如果有意向選購的話,歡迎http://niuniury.com前來咨詢。

When using automatic welding equipment, operators should know the relevant features, composition and other functions of the equipment in advance to avoid problems in later use. If you are interested in purchasing, welcome http://niuniury.com Come to consult.