焊接變位機(jī)送絲裝置的保養(yǎng)方法

來(lái)源:http://niuniury.com/ 發(fā)布時(shí)間:2022-11-24 瀏覽次數(shù):0

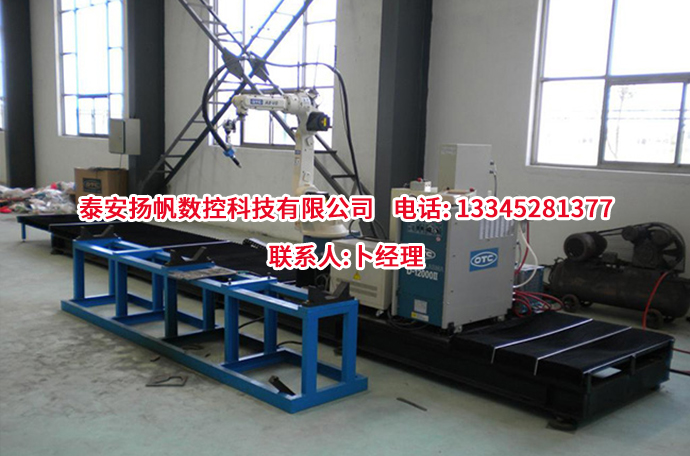

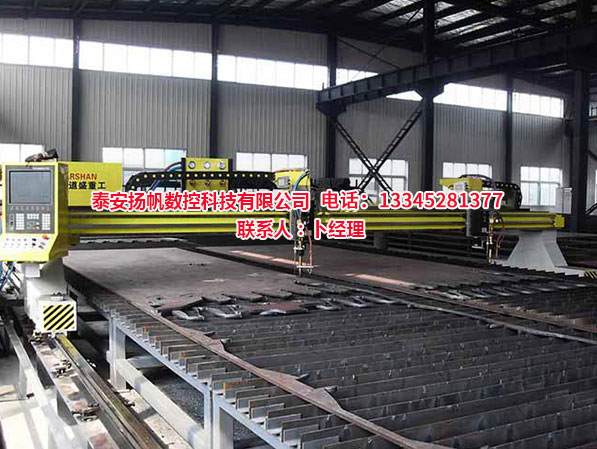

為了讓焊接變位機(jī)發(fā)揮它更好的作用,大家在平時(shí)的使用中要做好日常維護(hù)保養(yǎng)工作,以免因設(shè)備的損壞影響后續(xù)的應(yīng)用,帶來(lái)一系列麻煩。接下來(lái)山東數(shù)控焊接設(shè)備廠家就為大家介紹下焊接變位機(jī)送絲裝置的保養(yǎng)方法。

In order to make the welding positioner play a better role, we should do a good job in daily maintenance, so as not to affect the subsequent application due to equipment damage and bring a series of troubles. Next, Shandong CNC welding equipment manufacturer will introduce the maintenance method of wire feeder of welding positioner.

(1)加壓力調(diào)整。送絲輥輪加壓力要根據(jù)所用的焊絲直徑適當(dāng)?shù)卣{(diào)節(jié)。如果壓力不足,焊絲將打滑;壓力過(guò)大,焊絲將被刻傷、變形。

(1) Pressure adjustment. The wire feeding roller pressure shall be adjusted appropriately according to the diameter of the welding wire used. If the pressure is insufficient, the welding wire will slip; If the pressure is too high, the welding wire will be scratched and deformed.

(2)焊絲矯直裝置的調(diào)整。焊絲矯直裝置的調(diào)整方法按機(jī)種的不同而異,要根據(jù)焊接變位機(jī)廠家的標(biāo)示調(diào)整到相應(yīng)焊絲直徑的適合位置。

(2) Adjustment of welding wire straightening device. The adjustment method of the welding wire straightening device varies according to different models, and it shall be adjusted to the appropriate position of the corresponding welding wire diameter according to the marks of the welding positioner manufacturer.

(3)焊絲盤的安裝。若安裝不到位,焊絲盤在旋轉(zhuǎn)中就有掉下來(lái)的危險(xiǎn),產(chǎn)生嚴(yán)重后果,要好好檢查制動(dòng)塊或插銷是否可靠地裝上。

(3) Installation of welding wire reel. If the installation is not in place, the welding wire disc may fall down during rotation, which may cause serious consequences. Check whether the brake block or latch is reliably installed.

(4)送絲輪及所用的焊絲直徑。一定要裝上適合于所用焊絲直徑的送絲輪,并檢查滾輪上所刻的數(shù)字是否與所用焊絲直徑一致。

(4) Wire feed wheel and diameter of welding wire used. Be sure to install a wire feeding wheel suitable for the diameter of the welding wire used, and check whether the number engraved on the roller is consistent with the diameter of the welding wire used.

(5)送絲滾輪溝槽的磨耗污損。檢查送絲滾輪的溝槽是否磨耗,溝槽表面是否刻傷,溝槽中是否粘附著塵埃、鐵粉、焊絲鍍屑等。清理時(shí)要用棉紗抹布等揩凈。

(5) Wear and dirt of wire feeding roller groove. Check whether the groove of wire feeding roller is worn, whether the groove surface is scratched, and whether dust, iron powder, welding wire plating scraps, etc. are stuck in the groove. Wipe with cotton gauze rag when cleaning.

(6)導(dǎo)絲嘴的檢查。裝設(shè)于送絲滾輪前后的導(dǎo)絲嘴磨損或與送絲滾輪不水平,就會(huì)引起焊絲彎曲,送絲不穩(wěn)定,因此,一定要定期檢查和維修。

(6) Inspection of wire guide nozzle. If the wire guide nozzle installed at the front and back of the wire feeding roller is worn or not level with the wire feeding roller, the welding wire will be bent and the wire feeding will be unstable. Therefore, regular inspection and maintenance must be carried out.

所以提醒您要定期做好檢測(cè)工作。比如查看焊機(jī)通電時(shí),冷卻風(fēng)扇之旋轉(zhuǎn)是否平順,是否有異常的振動(dòng),聲音和氣味發(fā)生,氣體是否有漏泄等。更多相關(guān)內(nèi)容就來(lái)我們網(wǎng)站http://niuniury.com咨詢!

Therefore, I remind you to do a good job of testing regularly. For example, check whether the cooling fan rotates smoothly, whether there is abnormal vibration, sound and smell, and whether there is gas leakage when the welding machine is powered on. More relevant content will come to our website http://niuniury.com consulting service

上一篇:關(guān)于自動(dòng)焊接設(shè)備的基本構(gòu)成

下一篇:焊接專機(jī)設(shè)備操作規(guī)范參考信息