使用焊接專機前的基本設(shè)備了解

來源:http://niuniury.com/ 發(fā)布時間:2022-12-13 瀏覽次數(shù):0

在使用焊接專機之前,技術(shù)人員須先了解設(shè)備并了解其基本組成,以便他們能夠更好地工作。那么,您對設(shè)備了解多少?以下是山東焊接專機廠家為你介紹的信息,僅供參考。

Before using the special welding machine, technicians must first understand the equipment and its basic composition, so that they can work better. So, how much do you know about the equipment? The following information is introduced to you by Shandong welding machine manufacturer for reference only.

(一)焊接功率

(1) Welding power

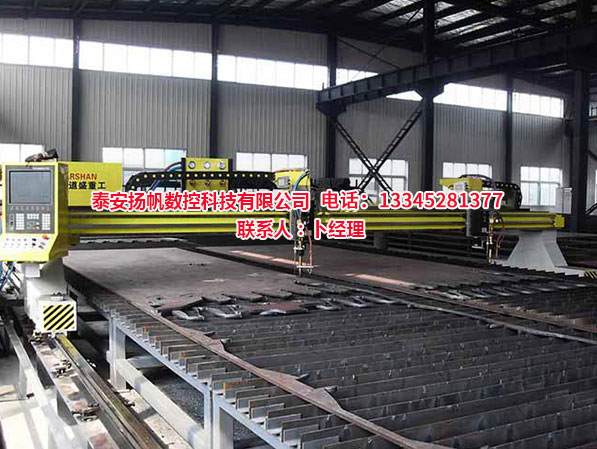

使用焊接專機機械零件時,確保加工很重要。因此,在選擇焊接電源時,請選擇逆變器脈沖電源以確保完全數(shù)字化的特性。此外,將電源連接到控制系統(tǒng)時,請確保該接口同時支持這兩種連接,并且可以查看相關(guān)的焊接參數(shù)。

It is important to ensure machining when using the mechanical parts of the welding machine. Therefore, when selecting the welding power supply, please select the inverter pulse power supply to ensure the fully digitized characteristics. In addition, when connecting the power supply to the control system, make sure that the interface supports both connections and can view relevant welding parameters.

您可以使用示教器輸入焊接參數(shù)。調(diào)整參數(shù)時,請根據(jù)實際焊接要求進行在線調(diào)整。此外,與手動焊接不同,與設(shè)備焊接零件時,應(yīng)選擇更高的電線和電流規(guī)格。

You can use the teaching pendant to enter welding parameters. When adjusting parameters, please make online adjustment according to actual welding requirements. In addition, unlike manual welding, higher wire and current specifications should be selected when welding parts with equipment.

(二)主體與控制器

(2) Main body and controller

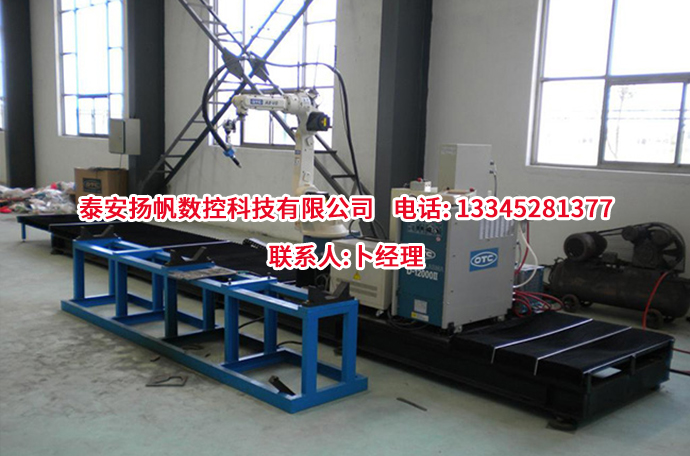

設(shè)備的主要結(jié)構(gòu)和控制器是重要的部分。主要結(jié)構(gòu)類型通常是6軸關(guān)節(jié)類型。要滿足的條件如下。所使用的采礦材料具有很高的耐腐蝕性,并且不得具有放射性。其結(jié)構(gòu)形式堅固而堅固。自動焊接主體的驅(qū)動力主要來自交流伺服。

The main structure and controller of the equipment are important parts. The main structure type is usually 6-axis joint type. The conditions to be met are as follows. The mining materials used have high corrosion resistance and shall not be radioactive. Its structural form is firm and firm. The driving force of automatic welding body mainly comes from AC servo.

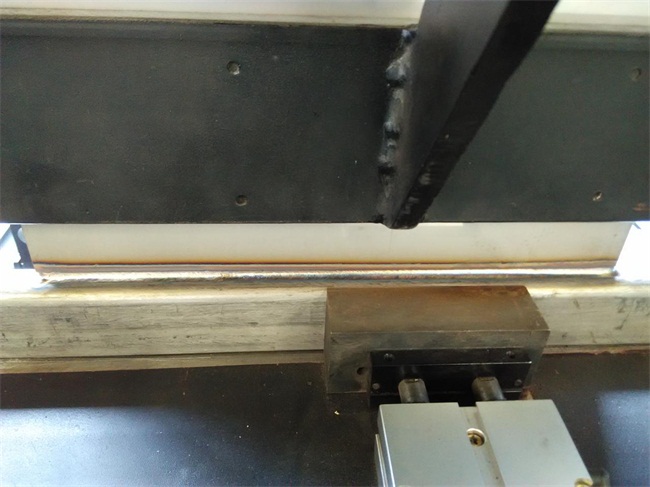

路徑測量系統(tǒng)配備有位置信息以保持動態(tài)特性。焊接精度可以滿足實際生產(chǎn)要求。此外,整個系統(tǒng)通過現(xiàn)場總線進行數(shù)字控制,并且設(shè)備系統(tǒng)的所有控制功能都使用數(shù)字控制器來實現(xiàn)。

The path measurement system is equipped with position information to maintain dynamic characteristics. The welding accuracy can meet the actual production requirements. In addition, the whole system carries out digital control through the field bus, and all control functions of the equipment system are realized by the digital controller.

由于配電系統(tǒng)幾乎不會對設(shè)備控制系統(tǒng)產(chǎn)生電磁干擾,因此焊接設(shè)備可以顯示出良好的可重復(fù)性。另外,為避免控制器其他設(shè)備引起的粉塵污染,應(yīng)采取防塵措施,以確保整個設(shè)備系統(tǒng)的可靠性。

Since the power distribution system hardly produces electromagnetic interference to the equipment control system, the welding equipment can show good repeatability. In addition, in order to avoid dust pollution caused by other equipment of the controller, dust prevention measures shall be taken to ensure the reliability of the entire equipment system.

使用焊接專機前的基本設(shè)備了解在此就從兩個方面來進行認識,當(dāng)然為了確保使用期間不出意外,您還需要做好檢查維護的工作,具體的內(nèi)容您可以來我們網(wǎng)站http://niuniury.com進行咨詢!

The basic equipment before using the special welding machine is understood from two aspects. Of course, in order to ensure that there are no accidents during the use, you also need to do a good job in inspection and maintenance. You can visit our website for details http://niuniury.com Consult!

上一篇:自動焊接設(shè)備可以焊接哪些工件

下一篇:怎么選擇焊接機器人的工件附件